Since 2011 we have honed our experience in SIPs assembly and install. More recently we have developed a specialist sub contracting service.

We now operate a panel assembly and install service for not only our own clients, but other builders and homeowners who wish to utilise our expertise and indoor facilities for this specialised area of their build.

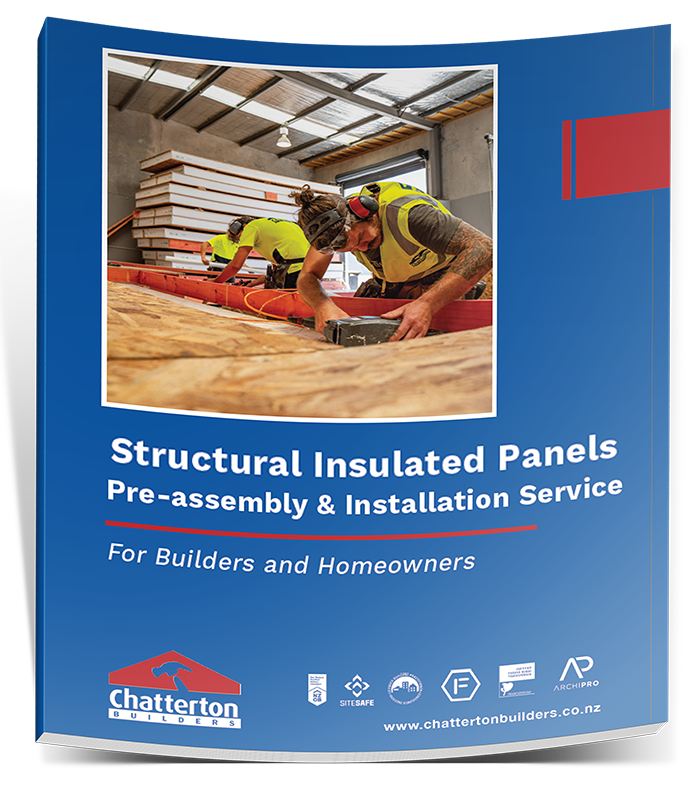

Our Indoor Plant, next door to our offices in Rangiora, allows us to assemble the panels unhindered by the weather and other building site activity. This saves time by improving efficiencies plus avoids the panels being exposed to the elements.

Our knowledge, experience and guaranteed price for this service reduces risk.

This service, if required, extends to assistance with the airtight layer and install of recessed windows into the airtight layer.

We have undertaken this specialist service for others in several locations, including Christchurch, Okuku, Greymouth, Dunedin, Diamond Harbour, Hanmer, Lake Brunner, and even Invercargill, with more projects in the pipeline.

Whether it’s a full build contract using our craftsmen builders, a SIPS assembly and install service, or SIPs assembly only (for those jobs further afield), we have the experienced team to assist you.